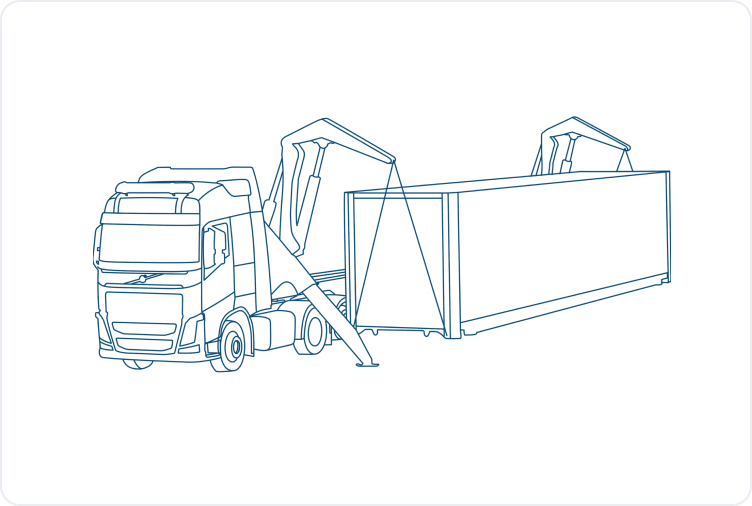

Sideloaders, also known as sidelifter or swinglift cranes, have revolutionized the container handling industry with their unique design and functionality. These articulated vehicles equipped with hydraulic lifting cranes offer remarkable lifting capacities and exceptional maneuverability. In this comprehensive post, we will explore the features, capabilities, and advantages of sideloaders in container transportation, along with important considerations when utilizing their services.

Unleashing the Power of Sideloaders

A sideloader is a specialized vehicle that boasts impressive lifting capabilities. It allows to handle containers with ease. With a lifting capacity of up to 32,000 kg, including the container weight, sideloaders ensure efficient loading and unloading operations. They employ powerful hydraulic cranes that can extend up to 1 meter away from the truck. That enables precise container placement on the left side of the vehicle, adjacent to the driver’s cabin. Furthermore, sideloaders can handle a wide range of container types: 20′, 30′, 40′, and 45′ containers. Such as DRY, HC, OT, PW, REF, and TANK. Their versatility extends to the transportation of two 20′ containers simultaneously. Each with a maximum weight of 10,000 kg. It’s worth noting that sideloaders are even capable of transporting containers classified as dangerous goods, complying with ADR and IMO regulations.

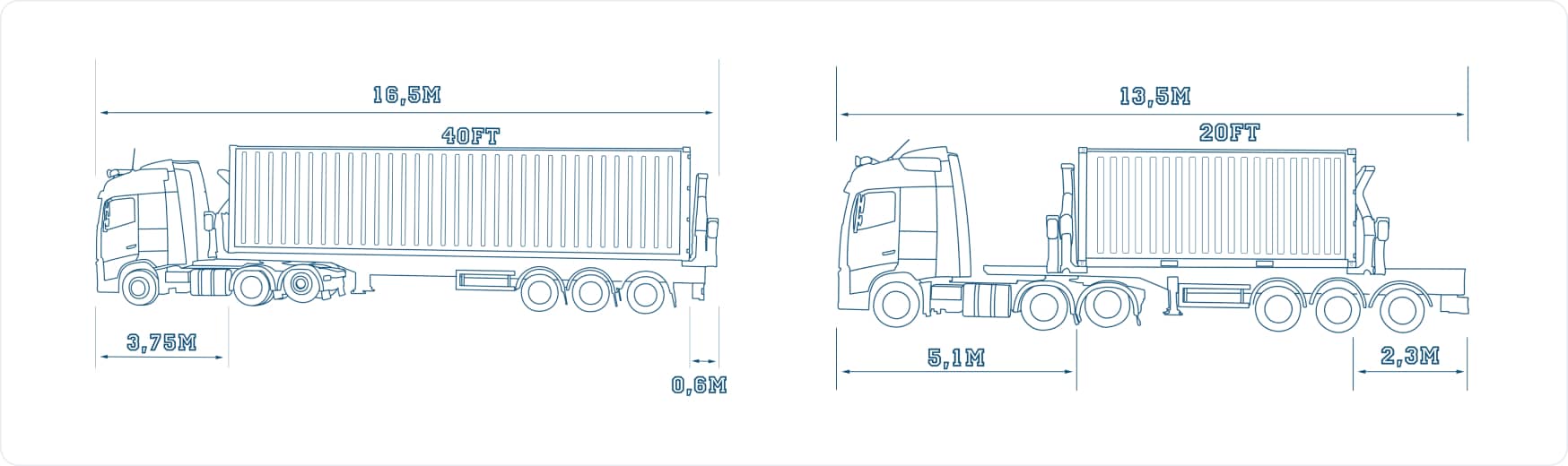

Exploring the Dimensions and Configurations

Understanding the dimensions of sideloaders is essential to ensure seamless container transportation. These vehicles come in various sizes and configurations, allowing for optimal adaptation to different container specifications. The dimensions of a sideloader play a vital role in determining its maneuverability and compatibility with different loading environments. With the right sideloader, you can navigate tight spaces, access challenging loading areas, and transport containers efficiently. When ordering transport services, it is crucial to communicate the preferred orientation of the container doors – whether facing the cabin or the rear. This ensures that the sideloader operator can accommodate the container’s placement precisely and plan the loading and unloading process accordingly.

Advantages of Sideloaders in Container Handling

Sideloaders offer numerous advantages that make them an indispensable asset in the container handling industry. Firstly, their ability to lift and transport containers independently means reduced reliance on external equipment. Such as cranes or forklifts. This efficiency translates into faster loading and unloading times. Optimizing productivity and minimizing operational costs. Additionally, sideloaders articulating capabilities enable them to load and unload containers onto various trailers and railway platforms, expanding their utility in intermodal logistics. Their versatility ensures seamless container transfers across different transportation modes, facilitating efficient supply chain management.

Safety Considerations and Best Practices

While sideloaders are powerful and versatile machines, safety should always be a top priority. Adequate training and certification for operators ensure the safe handling and operation of sideloaders. It is essential to adhere to all relevant safety guidelines and regulations to prevent accidents and ensure the well-being of personnel involved. Regular maintenance and inspection of sideloaders guarantee their optimal performance and reduce the risk of mechanical failures during operation. By prioritizing safety measures, you can create a secure working environment and protect the integrity of the transported containers.

Note! When ordering transport, please specify the orientation of the container doors: doors to cabin or doors to rear.